Optimizing Whistle Geometry for Enhanced Acoustic Performance

The Science Behind Whistle Acoustics

Whistles have been used for centuries across various cultures, from signaling in sports to emergency alerts. The acoustic performance of a whistle is deeply rooted in its geometry, which influences sound production, pitch, and volume. At its core, a whistle generates sound through the oscillation of air molecules, driven by the interaction between the air stream and the whistle's internal structure.

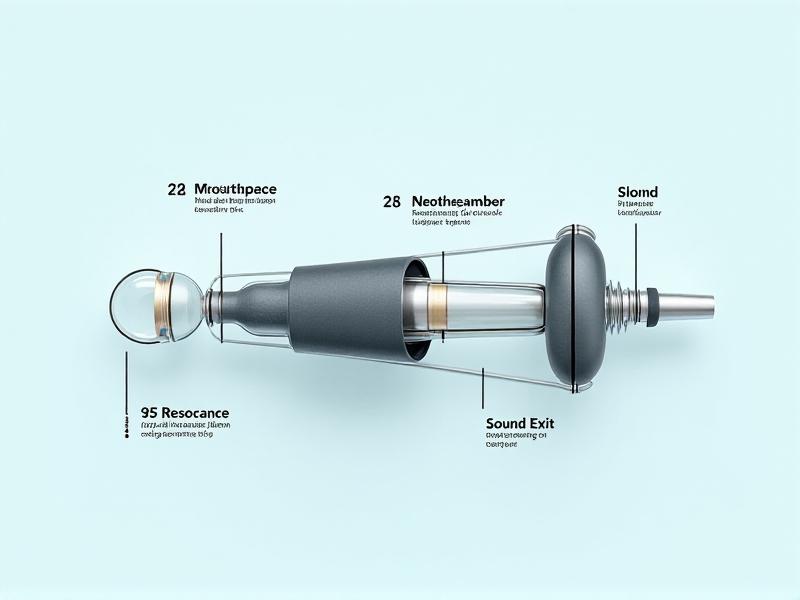

The geometry of a whistle includes factors such as the shape of the mouthpiece, the size and shape of the resonance chamber, and the design of the sound exit. These elements work together to create specific acoustic properties. For instance, a narrower mouthpiece can produce higher-pitched sounds, while a larger resonance chamber can amplify volume. Understanding these principles is essential for optimizing whistle design.

Modern advancements in computational fluid dynamics (CFD) and acoustic modeling have enabled researchers to simulate and analyze the behavior of air within a whistle. These tools provide insights into how different geometries affect sound production, allowing for precise adjustments to enhance performance. By combining theoretical knowledge with practical experimentation, it's possible to create whistles that meet specific acoustic requirements.

Key Factors Influencing Whistle Geometry

Several factors play a crucial role in determining the acoustic performance of a whistle. One of the most significant is the shape of the mouthpiece. A well-designed mouthpiece ensures efficient airflow, which is essential for consistent sound production. The angle and curvature of the mouthpiece can also affect the pitch and tone of the whistle.

Another critical factor is the size and shape of the resonance chamber. This chamber acts as an amplifier, enhancing the sound generated by the air stream. A larger chamber generally produces louder sounds, but the shape must be carefully designed to avoid distortions or unwanted harmonics. The material of the whistle also influences its acoustic properties, with denser materials typically producing clearer and more resonant sounds.

The design of the sound exit is equally important. The exit must be shaped to allow sound waves to propagate efficiently without interference. Factors such as the width and angle of the exit can significantly impact the whistle's overall performance. By optimizing these elements, designers can create whistles that deliver precise and reliable acoustic output.

Innovative Materials and Their Impact on Whistle Design

Traditionally, whistles were made from materials like metal, wood, or plastic. However, advancements in material science have introduced new options that can enhance acoustic performance. For example, composite materials can be engineered to provide specific acoustic properties, such as increased resonance or reduced weight.

One innovative material gaining popularity is carbon fiber. Known for its strength and lightness, carbon fiber can be used to create whistles that are both durable and acoustically superior. Thermoplastics, another material, can be shaped into intricate forms to maximize sound generation and provide design freedom.

The choice of material also affects the whistle's durability and usability. For instance, a whistle designed for outdoor use must withstand environmental factors like moisture and temperature changes. By selecting materials that balance acoustic performance with practical considerations, designers can create whistles that excel in real-world applications.

Case Studies: Successful Whistle Designs

Examining successful whistle designs provides valuable insights into the principles of optimizing geometry for acoustic performance. One notable example is the Fox 40 whistle, widely used in sports and emergency situations. Its pealess design eliminates moving parts, ensuring reliable sound production even in wet conditions. The whistle's geometry is carefully engineered to produce a loud, piercing sound that can be heard over long distances.

Another example is the Acme Thunderer, a classic whistle known for its distinctive tone. The Thunderer's design features a curved mouthpiece and a cylindrical resonance chamber, which work together to produce a clear, resonant sound. These case studies demonstrate how thoughtful design and precise geometry can result in whistles that meet specific performance criteria.

By analyzing these and other successful designs, researchers can identify common principles and apply them to new projects. This approach not only enhances acoustic performance but also ensures that whistles are practical and user-friendly.

Future Trends in Whistle Design and Acoustic Optimization

The future of whistle design lies in the integration of advanced technologies and innovative materials. One emerging trend is the use of 3D printing, which allows for rapid prototyping and customization. Designers can experiment with complex geometries that were previously impossible to achieve using traditional manufacturing methods.

Another trend is the incorporation of smart technologies, such as sensors and wireless connectivity. These features can enable whistles to provide real-time feedback on performance or integrate with other devices for enhanced functionality. For example, a whistle equipped with a sensor could measure the force of the air stream and adjust its geometry accordingly to optimize sound production.

Research will eventually produce whistles that are not just acoustically better but also more flexible and user-friendly. By embracing these trends, designers can push the boundaries of what is possible in whistle design and create products that meet the evolving needs of users.