Innovative Whistle Designs for Low-Frequency Sound Emission

The Science Behind Low-Frequency Sound Emission

Low-frequency sound emission is a fascinating area of acoustics that deals with sounds typically below 200 Hz. These sounds are often felt more than heard, making them ideal for applications where subtlety is key. Understanding the physics behind low-frequency sound is crucial for designing effective whistles. The wavelength of low-frequency sounds is much longer than that of high-frequency sounds, which means they can travel further and penetrate through obstacles more effectively. This characteristic makes them particularly useful in environments where high-frequency sounds might be absorbed or scattered.

When designing a whistle for low-frequency sound emission, it's essential to consider the materials and shape of the whistle. The material affects the sound's quality and durability, while the shape determines how the sound waves are produced and propagated. For instance, a larger, more robust whistle made of metal might produce a deeper, more resonant sound compared to a smaller, plastic whistle. The internal structure of the whistle, including the air chamber and the mouthpiece, also plays a significant role in shaping the sound.

Historical Evolution of Whistle Designs

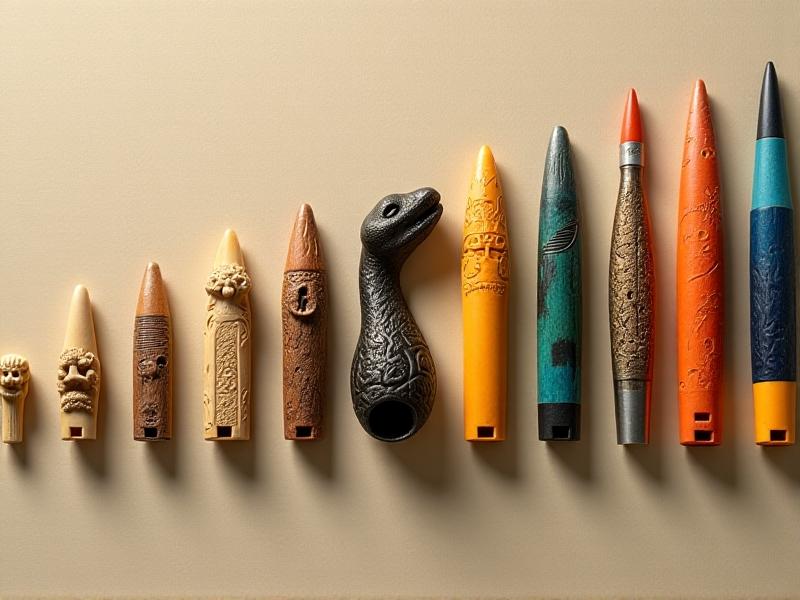

Whistles have been used for centuries, with their designs evolving significantly over time. Early whistles were simple, often made from natural materials like wood or bone. These rudimentary designs were primarily used for communication over short distances. As technology advanced, so did the complexity and functionality of whistles. The Industrial Revolution brought about the use of metals and plastics, allowing for more durable and versatile designs.

In the 20th century, the focus shifted towards creating whistles for specific purposes, such as sports, safety, and military applications. This period saw the development of whistles capable of producing a range of sounds, including low-frequency tones. The introduction of precision engineering and advanced materials further enhanced the performance of these devices. Today, whistle designs continue to evolve, with a growing emphasis on innovation and efficiency, particularly in the realm of low-frequency sound emission.

Key Principles in Designing Low-Frequency Whistles

Designing a whistle for low-frequency sound emission involves several key principles. First and foremost is the size of the whistle. Larger whistles are generally better suited for producing low-frequency sounds because they have larger air chambers, which allow for the generation of longer sound waves. The shape of the whistle also plays a crucial role. A cylindrical or conical shape can help in directing the sound waves more effectively, resulting in a clearer and more resonant tone.

Material selection is another critical factor. Dense materials like metal are often preferred for low-frequency whistles because they can produce a more robust and enduring sound. Additionally, the internal structure of the whistle, including the placement of the air holes and the design of the mouthpiece, must be carefully considered to optimize sound production. Finally, the ergonomics of the whistle should not be overlooked. A well-designed whistle should be comfortable to use, allowing the user to produce the desired sound with minimal effort.

Innovative Materials and Their Impact on Sound Quality

The choice of materials has a profound impact on the sound quality of a whistle. Traditional materials like wood and bone have been used for centuries, but modern materials offer enhanced performance and durability. Metals such as brass and aluminum are popular choices for low-frequency whistles due to their density and ability to produce a rich, resonant sound. These materials also offer excellent durability, making them suitable for long-term use.

In recent years, advanced composites and polymers have emerged as viable alternatives to traditional materials. These materials can be engineered to have specific acoustic properties, allowing for greater control over the sound produced. For example, certain polymers can be designed to absorb high-frequency sounds, resulting in a purer low-frequency tone. Additionally, these materials are often lighter and more resistant to environmental factors like moisture and temperature changes, making them ideal for outdoor use.

Applications of Low-Frequency Whistles in Modern Technology

Low-frequency whistles have a wide range of applications in modern technology. One of the most common uses is in safety and emergency signaling. The ability of low-frequency sounds to travel long distances and penetrate through obstacles makes them ideal for alerting people in large or noisy environments. For example, low-frequency whistles are often used in maritime settings to signal distress or communicate between ships.

In the field of sports, low-frequency whistles are used by referees and coaches to communicate with players. The deep, resonant tone of these whistles can be heard clearly over the noise of a game, ensuring that instructions are conveyed effectively. Additionally, low-frequency whistles are used in wildlife research and conservation. Researchers use these whistles to study animal behavior and communication, as many animals are more sensitive to low-frequency sounds.

Future Trends in Whistle Design and Sound Engineering

The future of whistle design is likely to be shaped by advancements in sound engineering and material science. One emerging trend is the integration of electronic components into traditional whistle designs. These electronic whistles can produce a wider range of sounds, including low-frequency tones, and can be easily adjusted to suit different environments and purposes. Additionally, the use of 3D printing technology is expected to revolutionize whistle manufacturing, allowing for the creation of highly customized and intricate designs.

Another promising area of research is the development of bio-inspired whistles. By studying the acoustic mechanisms of animals and insects, researchers can design whistles that mimic natural sounds. These bio-inspired designs could lead to more efficient and effective whistles, particularly in applications like wildlife conservation and environmental monitoring. As technology continues to evolve, the possibilities for innovative whistle designs are virtually limitless, promising exciting developments in the years to come.