From CAD to Prototype: Streamlining 3D Whistle Production

The Evolution of Whistle Design: From Concept to CAD

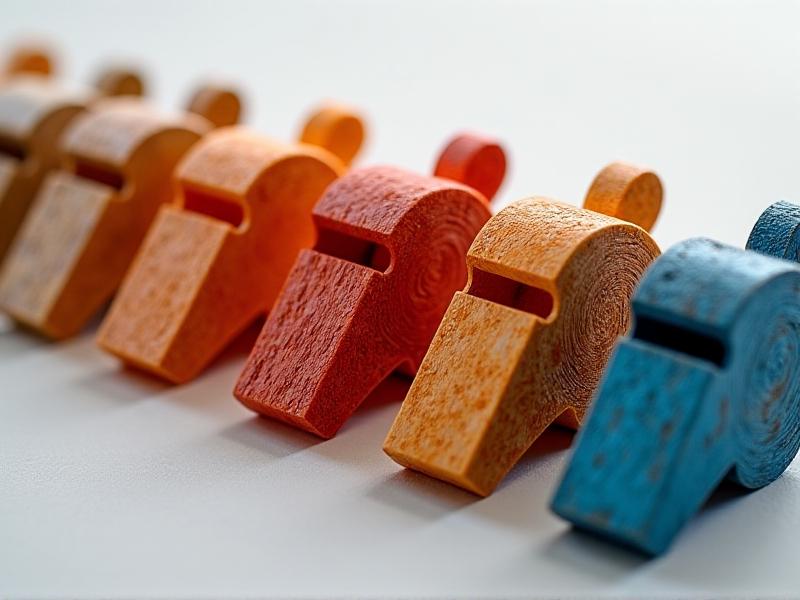

Whistles have been a staple in various industries, from sports to safety, for decades. However, the design process has evolved significantly with the advent of Computer-Aided Design (CAD). CAD software allows designers to create intricate 3D models with precision, enabling them to experiment with shapes, sizes, and materials before moving to the prototyping phase. This digital transformation has not only streamlined the design process but also opened up new possibilities for innovation.

In the early stages, designers brainstorm ideas and sketch rough concepts on paper. These sketches are then digitized into CAD software, where they are refined and optimized. The ability to visualize the product in 3D before it’s physically made is a game-changer. It allows for rapid iterations and adjustments, ensuring that the final design meets both aesthetic and functional requirements.

Material Selection: Balancing Durability and Acoustics

Choosing the right material is crucial in whistle production. The material not only affects the durability and longevity of the whistle but also its acoustic properties. Common materials include plastics, metals, and composites, each offering unique benefits. For instance, plastics are lightweight and cost-effective, while metals provide a robust and premium feel.

Acoustic performance is another critical factor. The material must resonate well to produce a clear, loud sound. CAD software can simulate how different materials will perform acoustically, allowing designers to make informed decisions. This simulation helps in selecting a material that offers the best balance between durability and sound quality, ensuring the whistle performs optimally in its intended environment.

Prototyping Techniques: Turning Digital Models into Physical Products

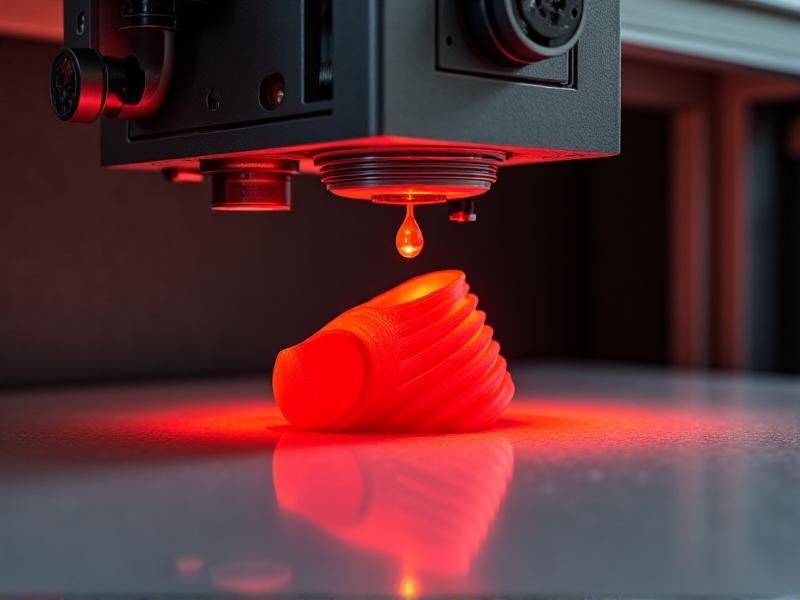

Once the design is finalized in CAD, the next step is prototyping. Prototyping transforms digital models into tangible products, allowing designers to test and validate their designs. There are several prototyping techniques available, including 3D printing, CNC machining, and injection molding. Each method has its advantages and is chosen based on the complexity of the design and the desired material properties.

3D printing is particularly popular for its speed and flexibility. It allows for rapid production of prototypes, enabling quick iterations and adjustments. CNC machining, on the other hand, is ideal for creating precise, high-quality prototypes from metal or plastic. Though it can also be used for prototyping to evaluate the manufacturability of the design, injection molding is used for mass production.

Testing and Validation: Ensuring Quality and Performance

Testing is a critical phase in the whistle production process. It ensures that the prototype meets the required standards for quality and performance. Various tests are conducted, including acoustic testing, durability testing, and ergonomic testing. Acoustic testing measures the sound output and frequency of the whistle, ensuring it is loud and clear enough for its intended use.

Durability testing assesses the whistle’s ability to withstand wear and tear, especially in harsh environments. Ergonomic testing evaluates the comfort and usability of the whistle, ensuring it can be easily operated by the end-user. Feedback from these tests is used to make final adjustments to the design, ensuring the final product is both functional and reliable.

Scaling Up: From Prototype to Mass Production

Once the prototype has been thoroughly tested and validated, the next step is scaling up for mass production. This involves selecting the appropriate manufacturing method and setting up the production line. Injection molding is commonly used for mass-producing plastic whistles, as it allows for high-volume production with consistent quality.

Metal whistles, on the other hand, are often produced using die-casting or CNC machining. The choice of manufacturing method depends on factors such as production volume, material, and cost. Scaling up requires careful planning and coordination to ensure that the production process is efficient and that the final product meets the desired quality standards.

Innovations in Whistle Design: What’s Next?

The future of whistle design is filled with exciting possibilities. Advances in materials science, manufacturing technologies, and CAD software are driving innovation in this field. For example, smart materials that can alter qualities according on environmental circumstances could provide whistles that fit various uses or climates.

Another area of innovation is the integration of electronics into whistles. Imagine a whistle that can record and transmit data, or one that can be controlled via a smartphone app. These advancements could revolutionize the way whistles are used in sports, safety, and other applications. As technology continues to evolve, the possibilities for whistle design are virtually limitless.