Customizable Whistle Designs: Personalization Through 3D Printing

The Rise of Customizable Whistle Designs

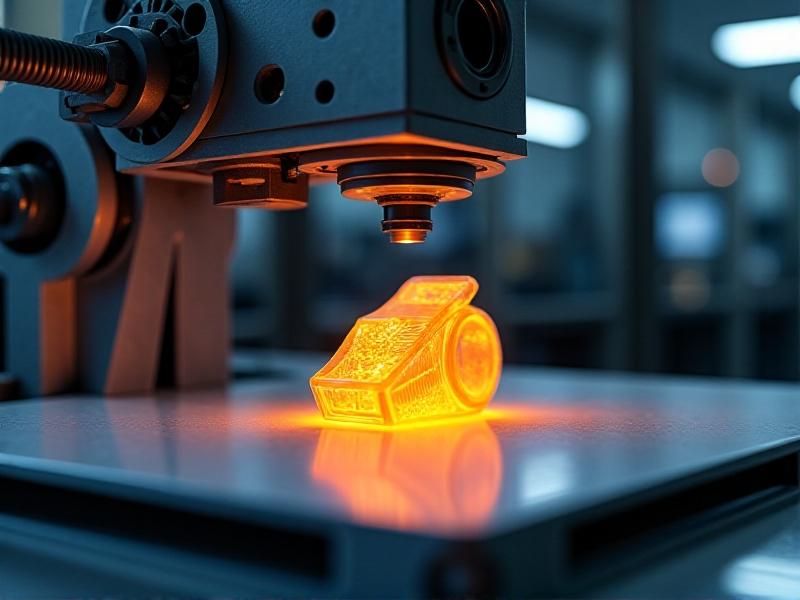

In recent years, the world of product design has seen a significant shift towards personalization, and whistles are no exception. With the advent of 3D printing technology, creating customizable whistle designs has become more accessible than ever. This innovation allows individuals to tailor whistles to their specific needs, preferences, and even aesthetic tastes. Whether for sports, safety, or collectibles, the ability to personalize whistles through 3D printing opens up a realm of possibilities that were previously unimaginable.

How 3D Printing Revolutionizes Whistle Manufacturing

Traditional whistle manufacturing often involves mass production techniques that limit customization. However, 3D printing has revolutionized this process by enabling the creation of unique, one-of-a-kind designs. This technology allows for intricate detailing, complex geometries, and the use of various materials, all of which contribute to the functionality and aesthetic appeal of the whistle. Moreover, 3D printing reduces waste and production costs, making it an environmentally friendly option. The ability to prototype and iterate quickly also means that designers can experiment with different shapes, sizes, and features to optimize the whistle's performance.

Personalization Options for Whistle Designs

One of the most exciting aspects of 3D printed whistles is the wide range of personalization options available. Users can choose from different colors, patterns, and materials to create a whistle that reflects their personality or meets specific requirements. For instance, a coach might want a whistle with their team's logo, while a hiker might prefer a lightweight, durable design. Additionally, 3D printing allows for the incorporation of ergonomic features, such as contoured grips or adjustable mouthpieces, enhancing comfort and usability. The possibilities are virtually endless, making each whistle a unique piece of functional art.

The Role of Software in Designing Custom Whistles

Designing a custom whistle involves more than just a 3D printer; it requires sophisticated software to bring ideas to life. CAD (Computer-Aided Design) programs are essential for creating detailed models that can be printed. These tools allow designers to experiment with different shapes, sizes, and features, ensuring that the final product meets the desired specifications. Additionally, software can simulate how the whistle will sound, allowing for adjustments to be made before printing. This combination of creativity and technology ensures that each whistle is not only visually appealing but also functionally effective.

Material Choices for 3D Printed Whistles

The choice of material plays a crucial role in the performance and durability of a 3D printed whistle. Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol), each offering different properties. PLA is biodegradable and easy to print with, making it a popular choice for beginners. ABS is more durable and resistant to impact, while PETG combines the best of both worlds with its strength and flexibility. For those looking for a premium option, materials like nylon or metal-infused filaments can be used to create whistles with a high-end finish. The material choice can significantly impact the whistle's sound quality, weight, and overall feel.

Applications of Custom Whistles in Various Fields

Customizable whistles have a wide range of applications across different fields. In sports, coaches and referees can use personalized whistles to enhance team spirit and professionalism. In outdoor activities, hikers and campers can benefit from lightweight, durable whistles designed for rugged environments. Safety professionals, such as lifeguards and security personnel, can use customized whistles to improve visibility and effectiveness in emergency situations. Even in the world of collectibles, 3D printed whistles offer a unique way to showcase creativity and craftsmanship. The versatility of customizable whistles makes them a valuable tool in many contexts.

Challenges and Considerations in Custom Whistle Design

While 3D printing offers numerous advantages, there are also challenges to consider when designing custom whistles. One of the primary concerns is ensuring that the whistle produces a clear, loud sound, which can be affected by the material and design. Additionally, the durability of the whistle must be taken into account, especially for those used in demanding environments. Another consideration is the cost and accessibility of 3D printing technology, which may be a barrier for some individuals. Despite these challenges, the benefits of customizable whistle designs often outweigh the drawbacks, making them a worthwhile investment for many users.

Future Trends in Customizable Whistle Designs

As 3D printing technology continues to evolve, the future of customizable whistle designs looks promising. Advances in materials and printing techniques are likely to result in even more innovative and functional designs. We can expect to see whistles with integrated technology, such as built-in GPS or sound amplification, as well as more sustainable options made from recycled materials. Additionally, the growing popularity of online platforms for sharing and selling 3D models will make it easier for individuals to access and customize whistle designs. The future holds endless possibilities for those looking to create unique, personalized whistles.

Conclusion: The Art and Science of Custom Whistles

Customizable whistle designs represent the perfect blend of art and science, combining creativity with cutting-edge technology. 3D printing has opened up new avenues for personalization, allowing individuals to create whistles that are not only functional but also a reflection of their personality and needs. From sports to safety, the applications of these whistles are vast and varied. While there are challenges to consider, the benefits of customizable designs make them a valuable tool in many fields. As technology continues to advance, the possibilities for custom whistle designs are limitless, promising an exciting future for this innovative product.