Case Studies: Innovative 3D-Printed Whistles in Modern Collections

The Evolution of Whistles: From Traditional to 3D-Printed Designs

Whistles have been a part of human history for centuries, serving as essential tools for communication, safety, and even entertainment. Traditionally crafted from materials like wood, metal, and plastic, whistles have undergone a remarkable transformation with the advent of 3D printing technology. This innovation has not only revolutionized the manufacturing process but also expanded the possibilities for design, functionality, and customization. In this section, we explore how 3D printing has redefined the whistle, turning it into a modern collectible and functional art piece.

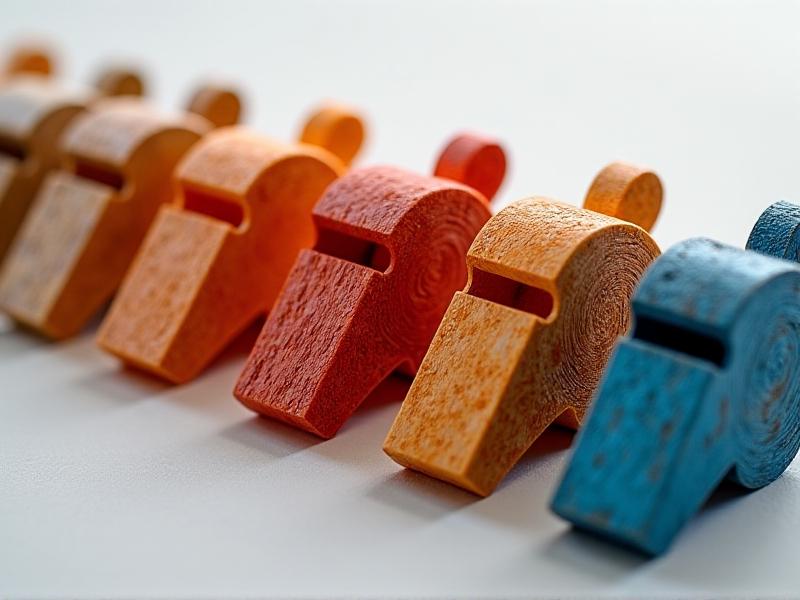

The Art of 3D-Printed Whistles: Design and Aesthetics

One of the most striking aspects of 3D-printed whistles is their aesthetic appeal. Unlike traditional whistles, which often follow a standard design, 3D-printed whistles can be customized to feature intricate patterns, unique shapes, and vibrant colors. Designers are now able to experiment with complex geometries and organic forms that were previously impossible to achieve. This section delves into the artistic potential of 3D-printed whistles, highlighting how they have become a medium for creative expression and a sought-after item in modern collections.

Functionality Meets Innovation: The Engineering Behind 3D-Printed Whistles

While aesthetics are important, functionality remains a key consideration in whistle design. 3D printing allows for precise engineering, enabling designers to optimize the acoustics, ergonomics, and durability of their creations. This section explores the technical aspects of 3D-printed whistles, from the materials used to the innovative techniques employed to enhance their performance. We also examine how these advancements have made 3D-printed whistles not just visually appealing, but also highly effective tools for their intended purposes.

Case Study: The Phoenix Whistle – A Blend of Art and Function

One of the most notable examples of innovative 3D-printed whistles is the Phoenix Whistle, a design that has garnered attention for its unique combination of artistry and functionality. Inspired by the mythical phoenix, this whistle features a flame-like design with intricate detailing and a bold color palette. In this case study, we take a closer look at the design process, the challenges faced, and the final product that has become a standout piece in modern collections.

The Role of 3D Printing in Customizable Whistles

Customization is one of the most significant advantages of 3D printing, and whistles are no exception. Whether it’s a personalized message, a unique shape, or a specific color scheme, 3D printing allows for a level of customization that traditional manufacturing methods cannot match. This section discusses how 3D printing has opened up new possibilities for creating bespoke whistles, catering to individual preferences and making them truly one-of-a-kind items.

Environmental Impact: Sustainable Practices in 3D-Printed Whistle Production

As the world becomes more conscious of environmental issues, sustainability has become a crucial factor in manufacturing. 3D printing offers several eco-friendly advantages, such as reduced material waste and the ability to use biodegradable or recycled materials. This section examines the environmental impact of 3D-printed whistles, highlighting how this technology is contributing to more sustainable production practices in the industry.

The Future of 3D-Printed Whistles: Trends and Predictions

The world of 3D-printed whistles is constantly evolving, with new trends and innovations emerging regularly. From advancements in materials and printing techniques to the integration of smart technology, the future holds exciting possibilities for this niche market. In this final section, we explore the potential developments in 3D-printed whistle design and production, offering insights into what collectors and enthusiasts can expect in the years to come.